How to Calibrate Engineers Levels

Engineers Levels (or machinist levels, precision levels) are essential tools required when aiming to level a surface, machine or piece of equipment. They are easy to use, can be extremely accurate and are highly portable, meaning they are a popular piece of equipment in many different trades and industries. However, it is vital that these levels are properly calibrated in order to fulfil their specifications of precision and accuracy. This article will guide you through a simple, yet effective way to calibrate an engineers level so that you can always have accurate readings or provide an excellent service.

In order to calibrate an engineer’s level, an adjustable flat surface that is mechanically stable is required. It does not need to be perfectly level to start with, but must be within the range of the level you are calibrating. The following steps must then be taken.

1) Clean the bearing surface, and the underside of the level to remove any dirt or dust. Then place the level onto the bearing surface ready for inspection.

2) Note the position of the bubble after it has settled, (settling time can be up to 15 seconds) and then turn the level by 180° and place back onto the surface in the same position as before.

3) Note again the position of the bubble after it has settled. If the level and the surface are set level, then the bubble will be central on both readings. If the level is set level, but the bearing surface is out of level, then the bubble will move in the same direction off-centre when the level is turned through 180°. The surface can then be adjusted by this amount. If the bearing surface is set level, and the level is out of level, then the bubble will move in different direction off-centre when the level is turned through 180°. The level can then be adjusted to read level. If the readings are different, then both the level and the surface need to be adjusted.

Consider this example:

EXAMPLE 1

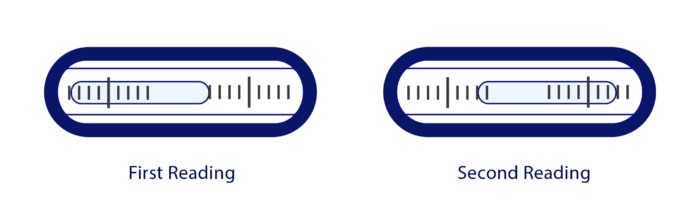

If the first bubble reading was 4 divisions to the left hand side, and the second reading when rotated through 180° was 3 divisions to the right hand side:

The error in the level is half of the total error = (4+3)/2 = 3.5 divisions.,

The error in the surface is half of the difference = (4-3)/2 = 0.5 divisions.

EXAMPLE 2

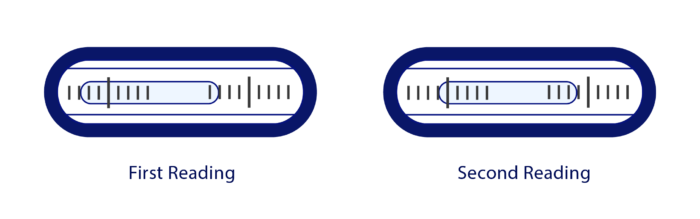

In the next example, the first reading is 3 divisions to the left, and the second reading when rotated through 180° was 1 division to the left-hand side:

The error in the level is half of the total error = (3-1)/2 = 1 divisions.,

The error in the surface is half of the difference = (3+1)/2 = 2 division.

Adjusting the level may differ from level to level, but they usually come supplied with an Allen key to turn the adjustment screw accessible from the top cover of the level. Other levels may have their own adjustment mechanisms. To find out more about our own range of Engineers Levels at Level Developments, visit our product pages on the right hand side.